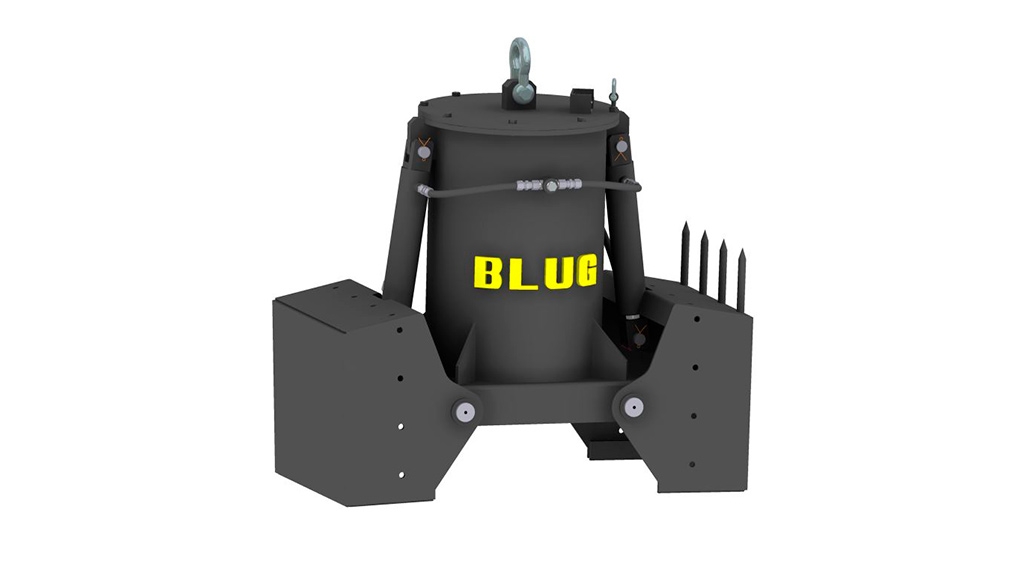

- Reinforced top cover with sealing gasket to protect the engine and hydraulic unit.

- High-pressure hydraulic cylinders.

- Clamshell design for dredge operations and complete load through maximum penetration force with wear resistant lips.

- Structure validated by Finite Elements Analysis.