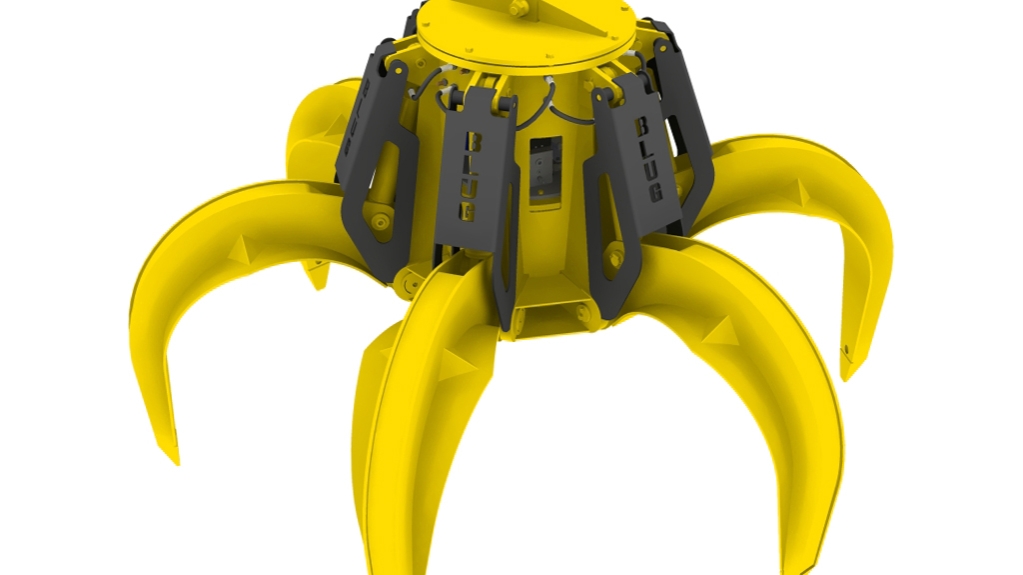

- Hydraulic unit equipped with self-regulated piston variable flow pump.

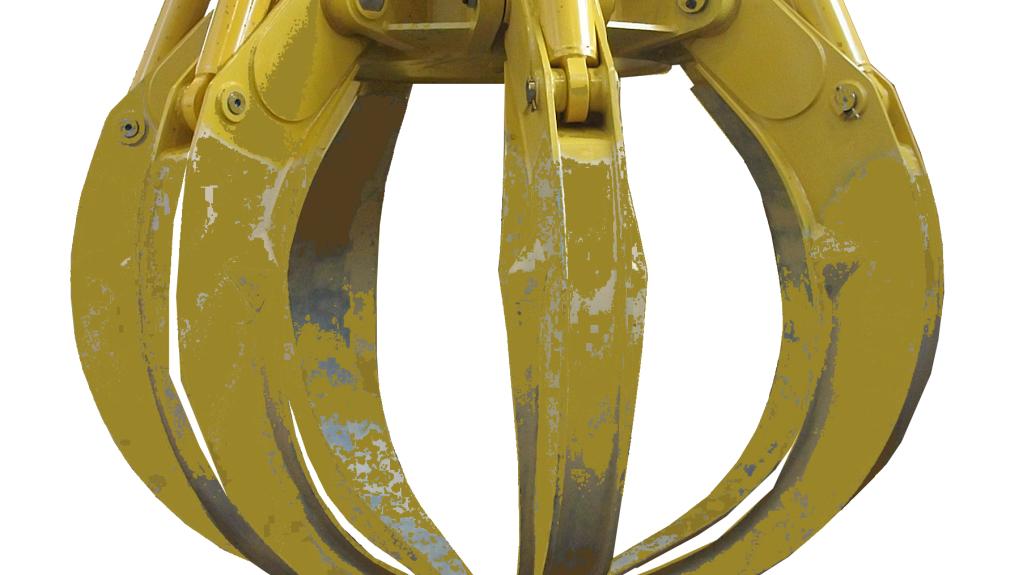

- Complete load through maximum penetration force applied with special profile jaws designed for the product.

- Full protected hydraulic cylinders.

- Special penetration teeth built in wear resistant manganese steel.

- Structure validated by Finite Elements Analysis.