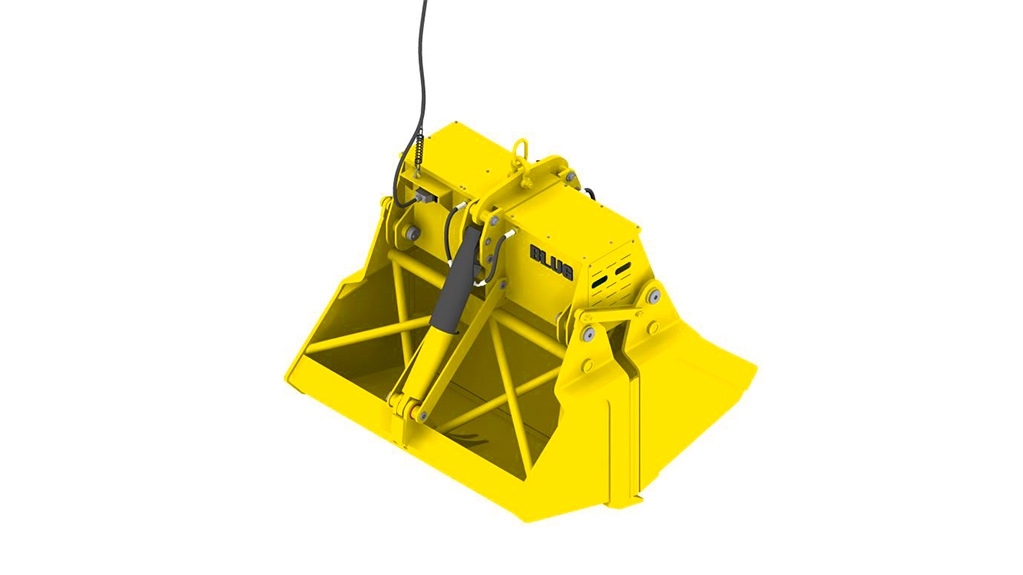

- Hydraulic unit in horizontal position to reduce grab´s height and equipped with self-regulated piston variable flow pump.

- Full protected hydraulic cylinders.

- Clamshell design with optimal penetration that allows full loading in all the operations thanks to a kinematic design at lifting and penetration mode including wear resistant lips.

- Structure validated by Finite Elements Analysis.